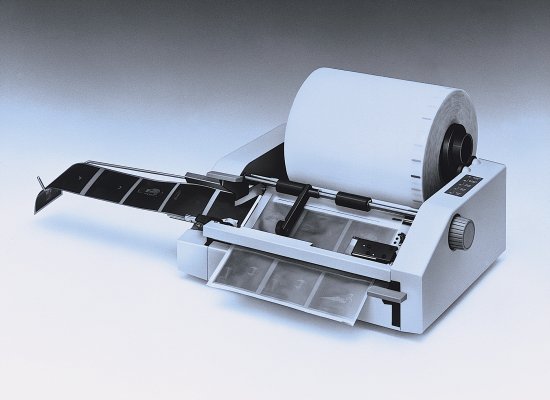

Film Sleever

Film strip is inserted automatically into sleeve, than adjust film frame to cut.Right after every film strip is cut, one section of sleeve is automatically forwarded to prepare for next film sleeving.

Sleeve can be cut off directly after one-order film sleeving has been completed without wasting extra sleeves.

Sleeve cutter is equipped with safety mechanism to protect film-cut by error.

-

Features

- Simple and safety operation.

- Almost full-automatic model renders high performance and high productivity.

- No wasting of extra sleeve-right after one order of film sleeving is completed, one section of sleeves is fed automatically and can be cut off.

- Compatible type for 120, 220, 135, 126 and 110 films.

- Sleeve cutter is equipped with safety device to protect film from mis-cut.

- Fixed-length film feed system.

- Easy mounting and smooth supply of sleeve without looseness and meandering.

- Easy sensor adjustment by outside sensor panel.

- Easy maintenance.

- Film Support arm prevents film feed-back for smooth film supply without trouble.

- Compact construction for space saving, designed in adequate view angle for efficient operation.

| Specifications | |

| : 120, 220, 135, 126 and 110 films. | |

| : Fixed-length feed System(4, 5 and 6 frames for 135) | |

| : 300m and 400m long sleeve in roll type. | |

| : One-touch cutter(safety device is equipped to protect film from mis-cut). | |

| : 230 rolls 120 film (12ex. 3 frames) per hour. | |

| : 250 rolls 135 film (24ex. 6 frames) per hour. | |

| : AC100V-265V, 50VA, 50/60Hz. | |

| : 457(W) X 335(D) X 158(H)mm | |

| : Approx. 8.0kg. | |